Technical Merino is technical fabrics developed for sport and functional garments. The combination of Merino wool and polyester gives advantages especially in areas of comfort and evaporation of moisture.

The products are composed of high quality yarns, knitted on the very best knitting machines, dyed and finished according to the directions demanded of the combination of Merino wool and polyester. Technical Merino further offers fabrics of 100% Merino wool in different weights and knit qualities.

The production of the fabric takes place in Denmark with flexibility, effectiveness and careful control all way through production.

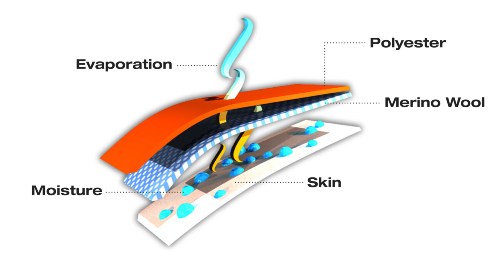

Technical Merino fabrics contain 3 elements:

Merino wool is an 100 % animal fibre which originates from the Merino sheep. Merino is the finest of wools and contains very long fibres with a fraction of the diameter in normal wool fibres. As a result Merino wool feels light and very soft. In regard to Technical Merino products, the most important quality is the hydrophobic (water-repellent) surface. It means the wool is able to transport moist almost without absorption which partly is due to the fact that a single Merino fibre contains up till 80% air. Furthermore, the single yarn contains many fibres which have the high capability of containing moist, so what cannot be transported away is absorbed without the Merino feels wet.

Actualy Merino wool is able to contain 35 % of moisture without feeling wet and even has an ability to keep warm in moist conditions. Merino wool regulates the temperature in a natural way by transporting moist away from the body. When it is cold the dry Merino wool absorbs the moist and starts an automatic process which generates heating. This phenomenon is called “heat of sorption”. When it is hot Merino wool feels colder by regulating the temperature down by evaporation. The body uses the same principle when we transpire.

Anti odour abilities are natural incorporated in the product. Merino wool has a natural resistance against micro organisms and garments can be used several days without getting a bad smell. The explanation is the fact that the Merino fibres are negative loaded and have a scaly surface. Micro-organisms, which are the reason for bad smells, thrives very well on a smooth and positive loaded surface which is the opposite of a Merino fibre.

Polyester is hydro absorbent (water absorbent). The polyester fibre has a larger surface containing more energy than the Merino fibre which means the moisture is seeking away from the Merino towards the polyester. The larger polyester surface means a larger area to spread out the moisture without the fabric feeling wet. Polyester has a very high drying capability and continually is able to absorb moist from the wool.

Dying and finishing of wool and polyester together is normally not a possibility. Special equipment and processes are therefore used to achieve the very best result. The correct finish of the fabric is necessary for the fibres ability to work together and get the wanted level of comfort and moisture control. We use only the best hydro absorbent softeners which improves the evaporation, comfort and soft hand feel of the products.

The compose of the 3 elements mentioned above in one fabric is a challenge! Though correctly carried out supreme qualities are achieved. The knitting of the fabric is made with 100 % Merino wool on the inside of the fabric and the polyester on the outside of the fabric. The Merino wool absorb/push the moist and the polyester soaks the moist to evaporate on the surface of the polyester.

Technical Merino is suitable for activities with high intensity such as running, cycling, skiing, climbing or work functions where the activity level changes from high to low and back.